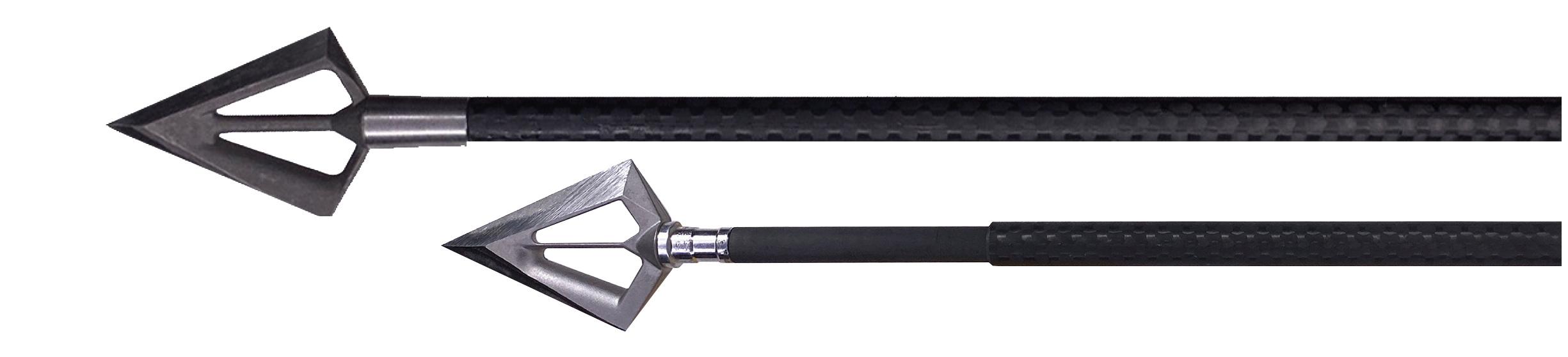

Dagger™

The Dagger, now available in two materials, in up to two approaches, and in up to seven weights, is our compound, single bevel grind equipped broadhead. To comprehend such a design, its important to start at a bevel.

Simply put, a bevel is a constant slope. In the instance of a weapon or, more specifically, a broadhead, such bevels are used to create a point or sharp edge. These usually involve double beveled edges, defined by a slope on both sides. Here is where the Dagger differentiates from all others—it does not have a slope on both its “sides,” it has a total of six complex beveled edges from all sides. See, a simple bevel involves, as aforementioned, a constant slope. Complex bevels, on the other hand, have multiple slopes. To clarify, the Dagger has two complex bevels on all of its edges and then two at its base. Each with its own individual slanted slope, these six bevels work together, are “compounded,” to provide rotation not only during initial contact with the game but all the way through the animal.

Dagger Titanium

Dagger Titanium or Ti is made from high pressure, die-cast GR5 Titanium and then machined processed. The Dagger Ti pulls its design near exactly from the original Dagger (DAGGER, 125 grains) to improve silent flight while still maintaining its weight at 85 grains. This light weight makes it an ideal broadhead for those who are using AeroConcept 1.0 or 2.0 due to the carbon inner tube’s (s’) already additional weight. Note that these come in single packs unlike all other Daggers, which come in packs of three.

New for 2021: MIM

Dagger was originally available in only two weights, 100 grains, for those who prefer a flat weight, and 125 grain for those who prefer a little heavier of a broadhead. Both were paced through a high-pressure die-cast (HPDC) process then machine processed. Note that, although extremely durable, HPDC processed stainless steel has an extremely low accuracy yield i.e., if 100 pieces were made, only 20% is +/-1 grain of the intended weight. Therefore, note that when purchasing DAGGER or DAGGEC today, there is some weight variance e.g. Dagger 125 could be 121-132 grains. When the possibility of using another process become possible in 2020, we jumped on it. Metal Injection Molding, or MIM, offered the opportunity to make broadheads with the complex geometry Dagger designs require without having to toss 80% of the lot. All Daggers will eventually be made via MIM and the HPDC series will be faded out.

Currently, eight stainless steel Daggers are available for purchase. The original two HPDC Dagger 100 and Dagger 125, as well as the six new

MIM Daggers from 100-250 grains. All Daggers are equipped with FACT, which includes the Double O-ring System on the neck for self-concentricity.

You can view each MIM Dagger (100, 125, 150, 175, 200 and 250 grain respectively) as a 3D rendering below.