AeroWeave™

A long time awaited, the AeroWeave Series is Firenock’s unique take on the arrow. Designed like all Firenock products, every aspect of this shaft’s design has been optimized—spine, weight and strength. To comprehend how exactly we “optimized” today’s carbon arrow, it is important to start at the beginning...

What exactly makes a carbon arrow different from another? In most cases, one thinks of diameter, ID or OD, etc. In reality however, the central difference between arrows is unseen, in how the carbon was manipulated during production. In the following sections, we aim to help you fully comprehend how arrows have been built over the years, from the fibers themselves to how they've been laid/woven. Note that, for this breakdown, we are assuming every lay is about the same weight.

Carbon Arrow Manufacturing

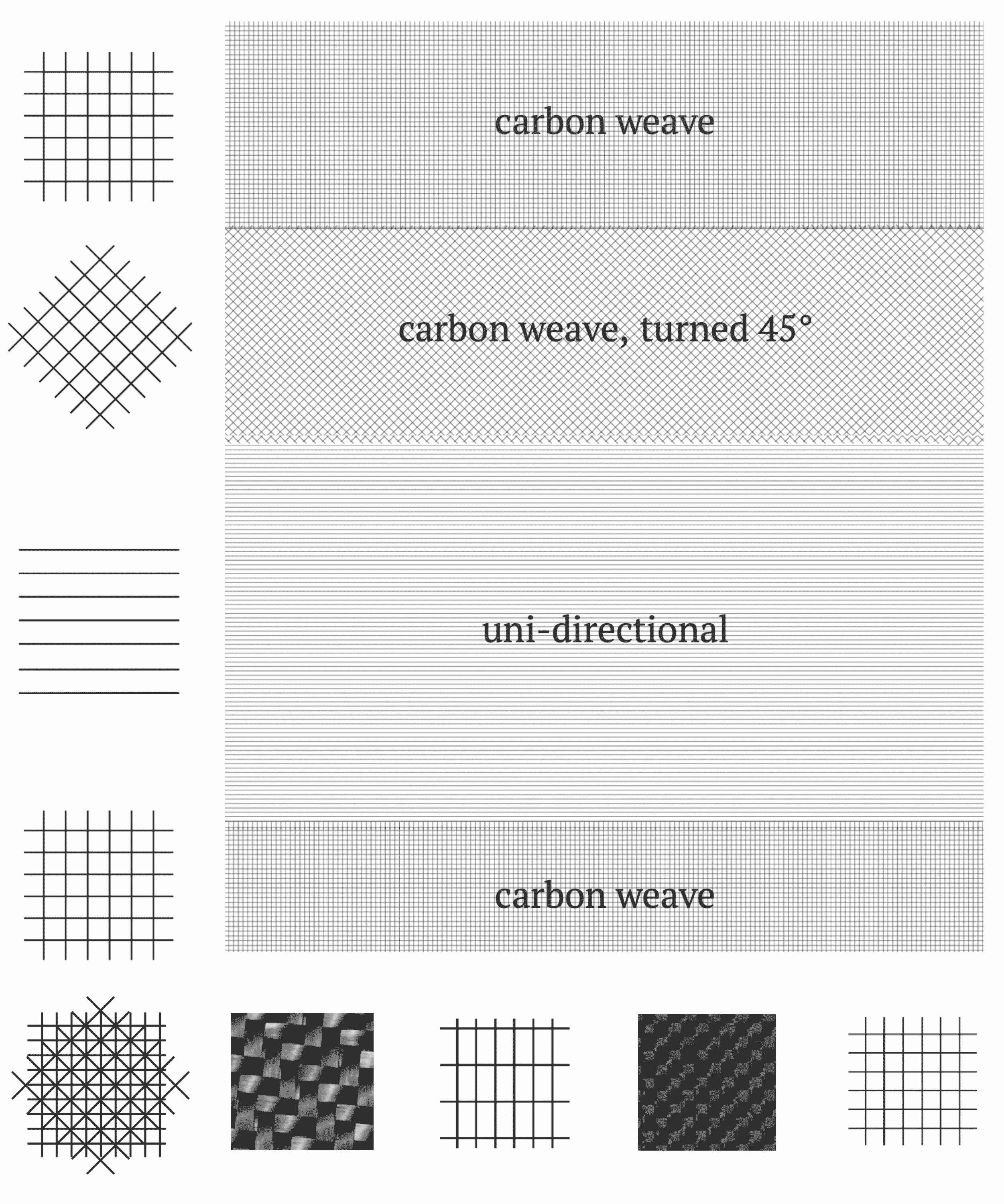

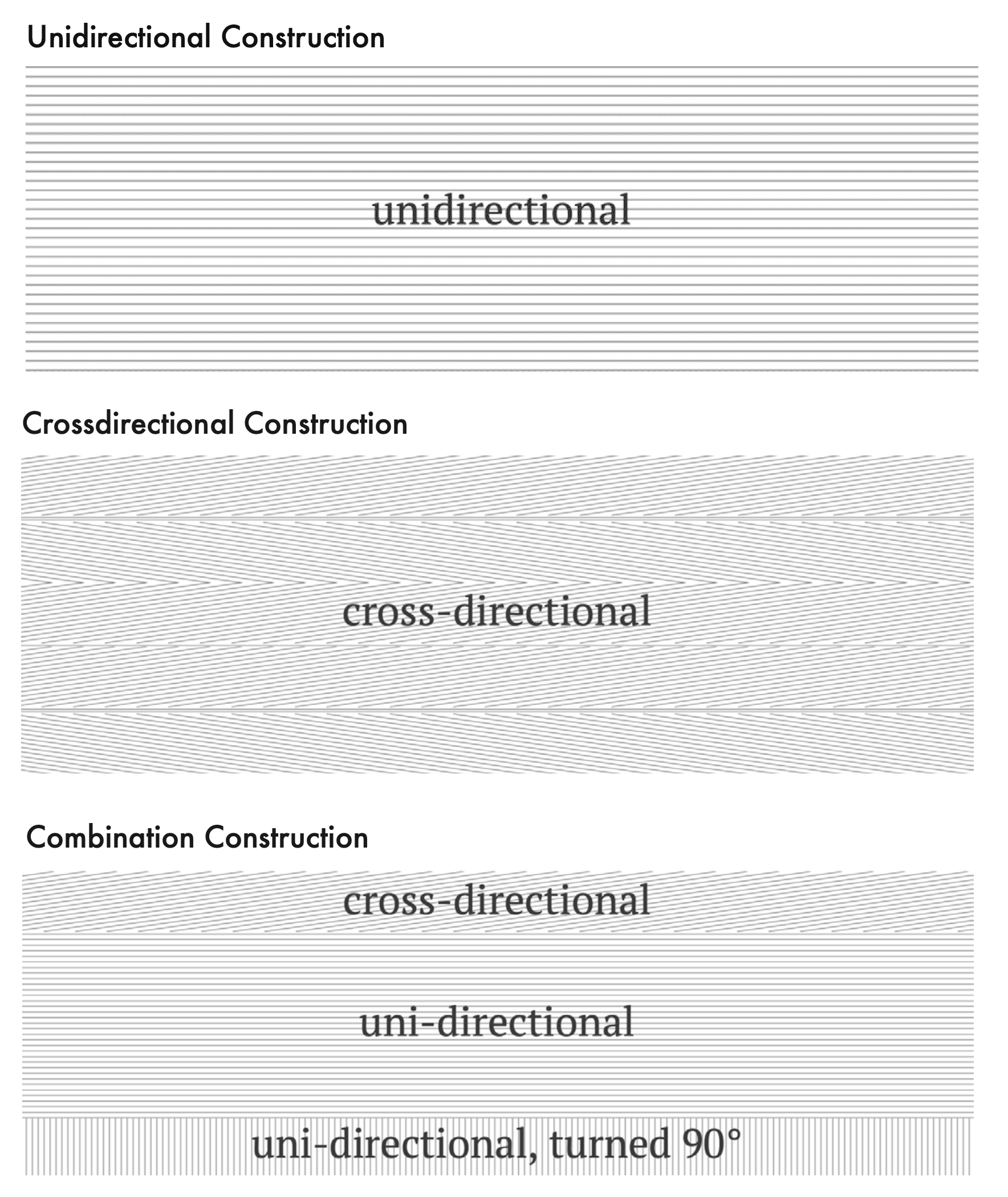

The first generation of arrows’ carbon fibers were set in simple linear rows before being rolled up. This method, although simple, does have benefits. Very light, unidirectional-ly laid arrows also have a very strong, very defined spine. There are issues too, however. But before going forward with what those issues are, it is important to clarify what measures are used to test the quality of an arrow. For this analysis, we will be using three measures in addition to spine: loop strength, torque strength, and torsion strength. Loop strength, simply put, is how much resistance an arrow has to direct compression. Torque and torsion strength, on the other hand, are connected. Both have to do with how much resistance an arrow has to being bent. The difference between them however is that while torque strength is associated with bending via one axis, torsion strength is associated with two or more axes. As an arrow is oscillating in space after launch, it is arguably bending/twisting on an infinite amount of axes.

The main issue with previous construction was how limited the aspect of the fibers were. Though this feature was actually what gave it its few pros (solidity/ rigidity = strong spine), the cons truly outweighed them therefore arrow manufacturing companies quickly adopted the cross-directional or helix wrap. Though its spine is not as strong or as light as the original, it has some loop strength and torque strength. As its name implies, this construction however is based on crossed directions, something covering two angles, maximum three if one part of the lay is uneven. As the chance for a hit from any angle is always possible in the world of archery, two or three protected angles is definitely not enough.

The last example of a common arrow constuction that is made today is a combination of the two previous constructions; this wrap’s spine and loop strength are their compromise. Its benefit, however, lies in its weight. Due to the majority of the fibers being laid linearly, the main (and only) advantage of this design is its light weight.

Firenock Weave Construction

And, finally, to Firenock’s AeroWeave arrow construction. First off, as you might have noticed, the diagram is much longer than the others. This was done intentionally. Therefore, how can an arrow that will be rolled the same and weight the same be so much longer? The carbon fibers used for AeroWeave shafts are of a different class. To maintain the same standard specifications but provide the most optimized arrow, Firenock uses ultra thin, ultra strong 4K fibers. And with thinner fibers, there is more lay for more manipulation.

While a large section of our construction takes from the original in that it has a linear lay for spine strength, its most unique feature is in its complex lays, its weaves (US Patent: 10,145,643). Due to the harsh environment of archery, strength at every axis is crucial. If you look closely, three of the four sections involve small squares. These squares are actually that “weave.” And those "diamonds" are also that weave, but rotated 45 degrees. But why does a weave matter? Well, with a weave, multiple axes can be covered at once. Further, if you turn that weave and lay it on top of itself, as will happen during the rolling of the carbon fibers, even more, infinitely more, axes will be protected.

But, of course, as we do for many Firenock products, we went a bit further. Consider the two photographs. This is an example of what most other weaves on the market look like. Do you see the difference between it and our weave (right)? Standard weave has a ratio of 2:1 (or sometimes even 3:1) and our weave has a ratio of 1:1. This allows for absolutely no gaps and balanced strength from all sides and axes. Again, a step further, but we at Firenock believe it’s worth it.

Note: Firenock AeroWeave shafts do not come with any arrow components. Firenock AeroWeave shafts are based on standard sizes; thus, there are plenty of common components that will fit each shaft. For reference, below are the component that Firenock offers that should fit each size.